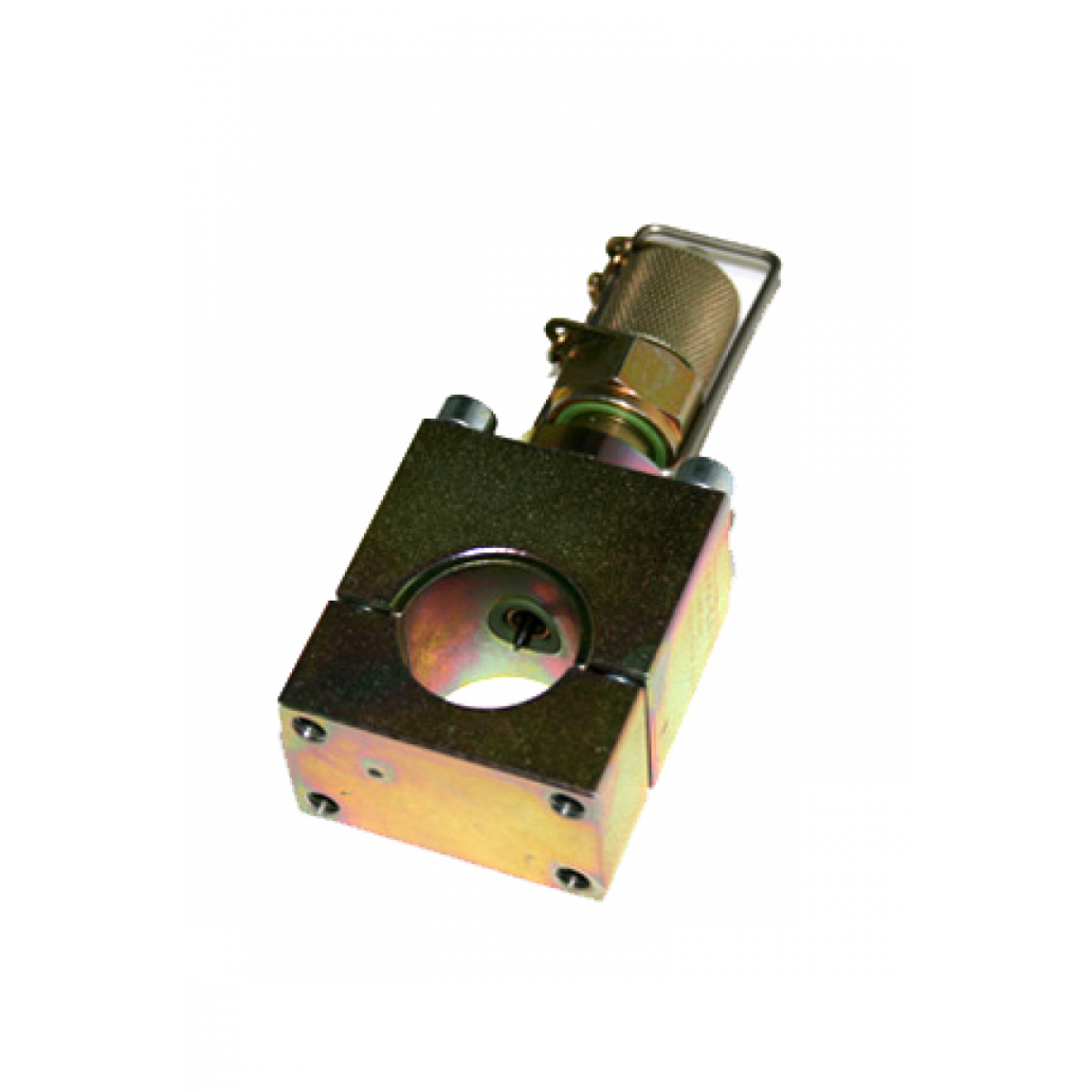

CheckFluid Pressureless Valve Mount 1-1/4 inch (for Pipe)

0 ratings | Submit a rating

$914.55

Easily Installed Sample Port

Valve Mounts allow for the easy installation of a sampling port on existing return lines.

Valve Mounts allow for the easy installation of a sampling port on existing return lines.

Brand: CheckFluid

Part Number:

VM2-P114

OVERVIEW

Valve Mounts are an ingenious way of getting around the conundrum of sampling from the system return line. On pressurized systems with a reservoir the recommendation is to sample from the return line. The irony is that the return line is, in almost all instances, devoid of any ports, or an easy place to install a sampling port. The Valve Mount gets around this problem by providing a way of installing a sampling port without the need for a complex retrofit of the return line.

SPECIFICATIONS

- Pipe Opening: 1-1/4"

- Height: 4.72" (120 mm)

- Width: 2.56" (65 mm)

- Housing: Steel

- Sealing Shell: Steel

- Seal: Viton

- Measuring Needle: Steel

- Maximum Operating Pressure: 9000 PSI

- Maximum Sampling Pressure: 6000 PSI

-

Pipe Requirements

Seamless drawn steel pipes made out of ST 35.4 material or pretreated basic material ST 37.4 according to DIN 1630. Condition when supplied NBA (normalising, bright annealed) with outer pipe diameter tolerances according to DIN 2391, maximum hardness: HRB 75. Construction dimensions of the Valve Mount System are adapted to the pipes tolerances according to DIN 2391. Pipe Requirements

Seamless drawn steel pipes made out of ST 35.4 material or pretreated basic material ST 37.4 according to DIN 1630. Condition when supplied NBA (normalising, bright annealed) with outer pipe diameter tolerances according to DIN 2391, maximum hardness: HRB 75. Construction dimensions of the Valve Mount System are adapted to the pipes tolerances according to DIN 2391.

FEATURES

- Add oil sampling and pressure measuring connections easily and safely while the system is shut down.

- After installation connection can stand up to 6000psi

- Installation in only a few minutes

- No special tools required.

- No cutting open pipes or special adapters required.

- Do not use on air or gas pipes.